Hey there, safety-conscious readers! Today, we’re diving into a topic that might sound a bit technical, but fear not – we’re here to break it down for you. Get ready to explore the world of machine guarding and discover why it’s crucial for your safety and the smooth operation of machines in various settings.

What Exactly is Machine Guarding?

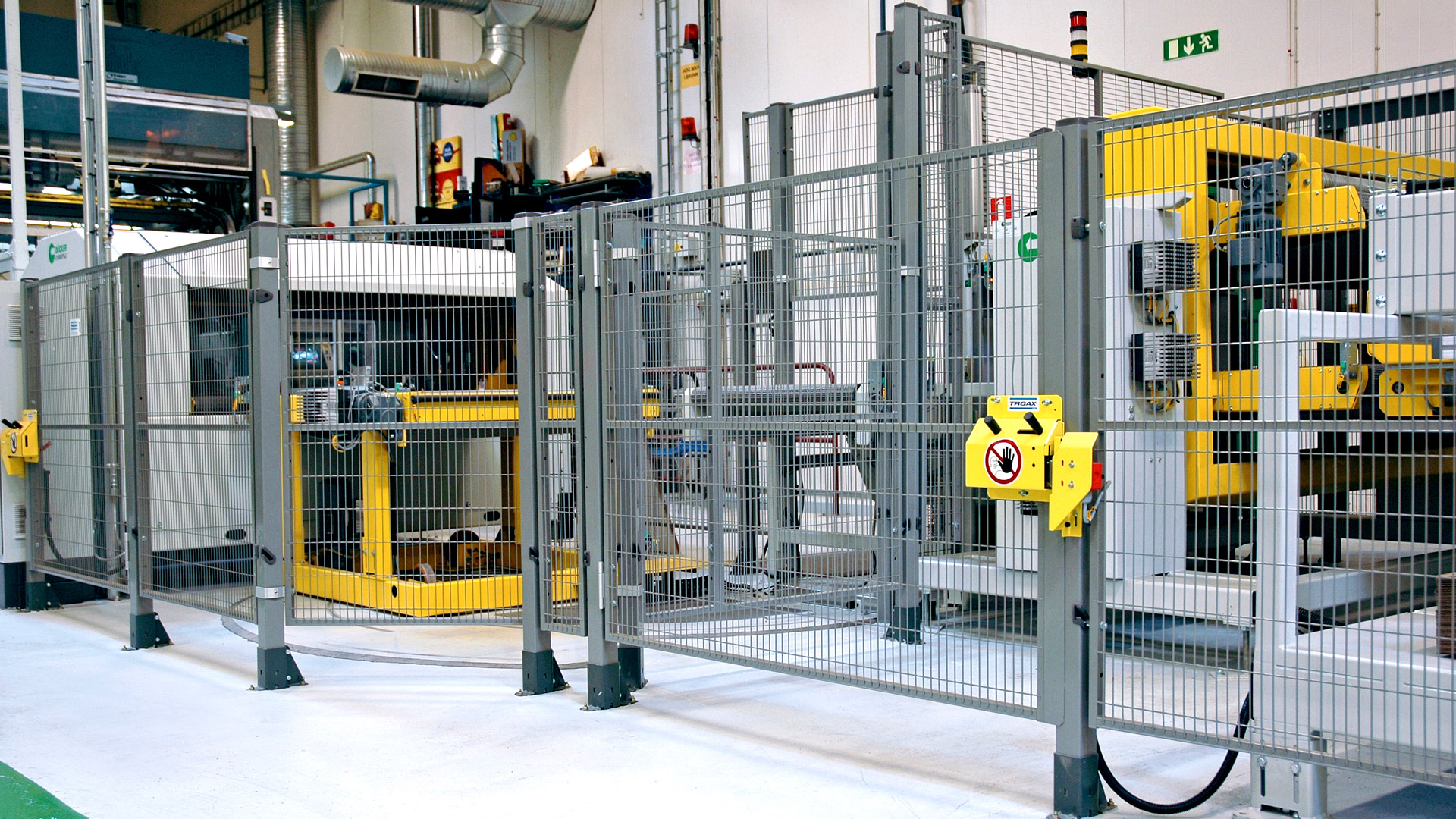

Imagine a superhero suit that protects a hero from harm – that’s the basic idea behind machine guarding. It’s like a protective shield for machines, ensuring they don’t pose a threat to humans working around them. This protective setup comes in various forms, from barriers and enclosures to safety devices that prevent accidental contact with hazardous parts.

The Why Behind Machine Guarding

So, you might be wondering, “Why all the fuss about machine guarding?” Well, friend, here’s the deal:

- Safety First: The most important reason. Machine guarding keeps you safe by reducing the risk of accidents, injuries, and even fatalities. It’s like having a safety net in place.

- Legal Requirements: Many countries have regulations mandating proper machine guarding. Ignoring these requirements can lead to hefty fines and legal troubles – definitely not something you want on your plate.

- Boosting Efficiency: Effective machine guarding doesn’t just protect you; it also helps the machines themselves. By preventing unintended interactions, the machinery can function more smoothly and efficiently.

Common Types of Machine Guarding

Common Types of Machine Guarding

Alright, let’s get into the nitty-gritty of guarding styles. There are a few different types to consider:

- Fixed Guards: These are sturdy, permanent barriers that physically prevent access to hazardous areas. Think of them as the fortress walls of the machine world.

- Interlocked Guards: These guards are like puzzle pieces – the machine only operates when the guard is in its proper place, ensuring you can’t accidentally come into contact with danger.

- Adjustable Guards: Need flexibility? These guards can be moved or altered to accommodate different sizes of materials and processes.

- Self-Adjusting Guards: Clever designs that adapt to the material being processed. They’re like the chameleons of the guarding world.

- Presence-Sensing Devices: These high-tech guards use sensors to detect when a person is too close to a dangerous area, causing the machine to stop before any harm occurs.

Your Role in the Safety Dance

Machine guarding might sound like a one-person show, but it’s a collaborative effort. Here’s how you can contribute:

- Stay Informed: Learn about the specific hazards associated with the machines you work with. This knowledge helps you understand the importance of proper guarding.

- Report Issues: If you notice damaged guards or safety hazards, don’t keep it to yourself. Speak up and report the problem to your supervisor or safety officer.

- Follow Procedures: Make sure to adhere to safety protocols and guidelines provided by your workplace. Proper training and responsible behavior go hand in hand.

The Takeaway

Remember, machine guarding isn’t just a safety requirement – it’s a mindset. By embracing effective guarding practices, you’re taking an active role in creating a safer work environment for yourself and your colleagues. It’s a win-win situation where everyone can thrive without unnecessary risks.

So, next time you see those trusty machine guards, give them a mental high-five for keeping you safe while you conquer the world of industry!