When it comes to working with machines, safety should always be a top priority. Without proper machine guarding, accidents and injuries can occur, resulting in devastating consequences for both employees and employers. In this blog post, we will explore the concept of machine guarding, its various types, the benefits it brings, and how it effectively prevents accidents and injuries. So, let’s dive in!

Understanding Machine Guarding

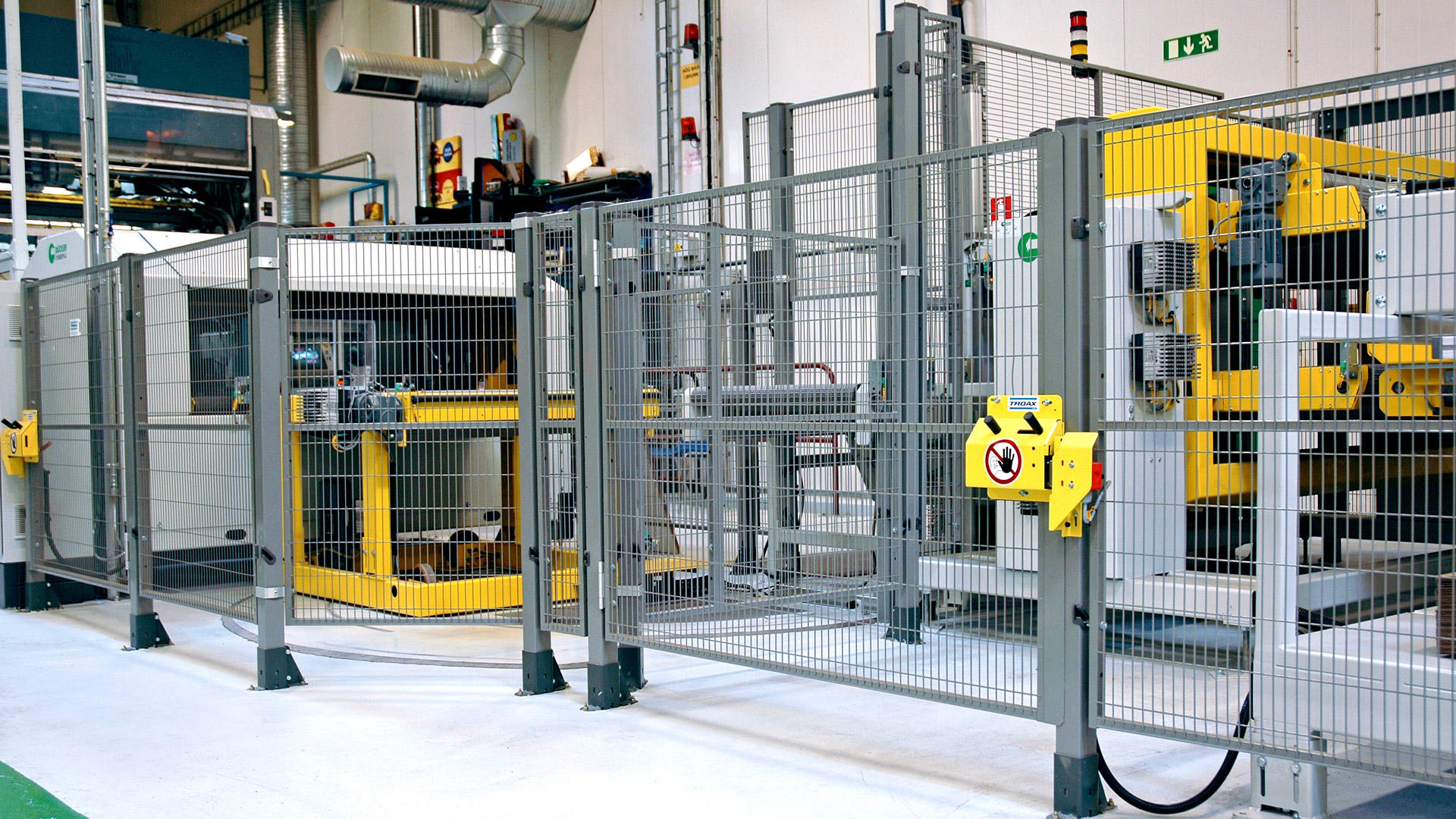

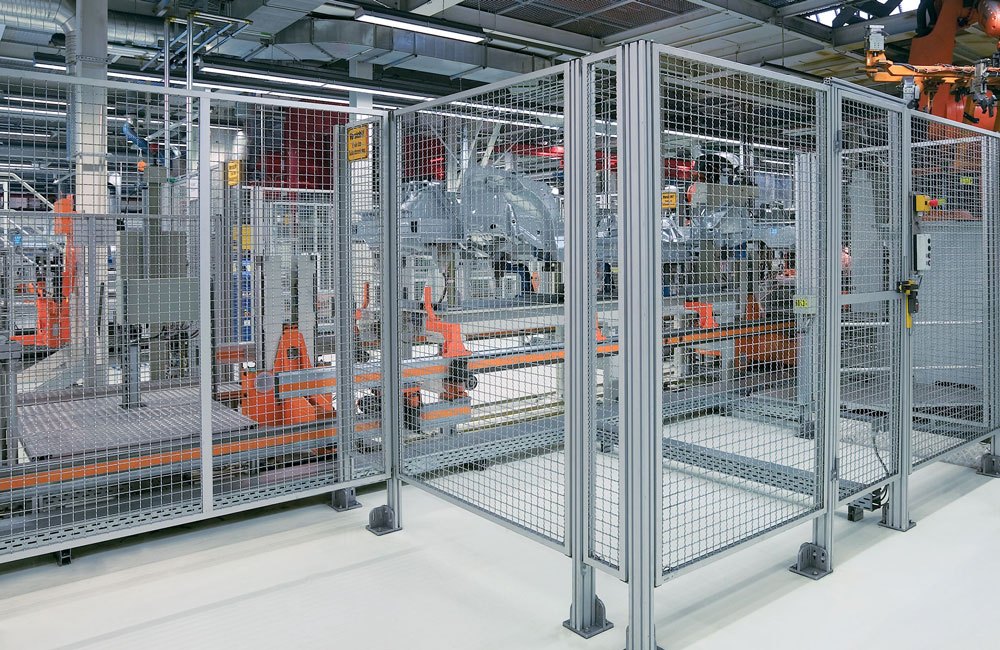

Machine guarding refers to the use of physical barriers or safety devices to protect workers from hazards associated with operating machinery. Its primary purpose is to prevent accidental contact with moving parts, such as blades, gears, belts, or other dangerous components. By implementing machine guards, employers can create a safe working environment and minimise the risks that come with using machinery.

There are different types of machine guards that can be utilised based on the specific requirements of a machine or task. The most common types include fixed guards, adjustable guards, and interlocked guards. Fixed guards are permanent barriers that provide a physical barrier between the worker and the moving parts of a machine. Adjustable guards, on the other hand, can be repositioned or removed to allow for maintenance or adjustments. Lastly, interlocked guards are designed to stop the machine from operating if the guard is not properly in place, ensuring the safety of the worker.

Benefits of Machine Guarding

Benefits of Machine Guarding

Machine guarding is a critical safety practice in industrial and manufacturing settings that involves the installation of physical barriers or safety devices to protect workers from the hazards posed by moving machinery and equipment. The benefits of machine guarding are numerous and far-reaching, contributing to both the safety and productivity of the workplace.

- Worker Safety: The primary purpose of machine guarding is to prevent accidents and injuries. It acts as a physical barrier that keeps workers away from dangerous moving parts, reducing the risk of amputations, crush injuries, and other severe accidents.

- Compliance with Regulations: Adhering to machine guarding requirements ensures compliance with occupational safety and health regulations. Compliance helps companies avoid costly fines and legal liabilities associated with workplace accidents.

- Increased Productivity: Properly guarded machines often result in increased productivity. When workers feel safe around equipment, they are more efficient and less prone to distractions or fear of accidents.

- Lower Workers’ Compensation Costs: Fewer accidents mean lower workers’ compensation costs for employers, as well as reduced downtime due to injuries.

- Enhanced Employee Morale: A safe work environment with machine guarding in place promotes employee morale and job satisfaction. Workers feel valued when their safety is a top priority.

- Longer Equipment Lifespan: Machine guarding can protect machinery from damage caused by unauthorised access or tampering, leading to longer equipment lifespan and reduced maintenance costs.

- Insurance Premium Reduction: Some insurance providers offer reduced premiums to companies that implement robust safety measures, including machine guarding.

How Machine Guarding Prevents Accidents and Injuries?

One prominent hazard that machine guarding helps mitigate is entanglement. Moving machine parts, such as rotating shafts or pulleys, can trap clothing, hair, or body parts, leading to severe injuries. By installing appropriate guards, the risk of entanglement is greatly reduced, ensuring that workers are protected from such accidents.

Machine guarding also prevents crush injuries, which can occur when a worker’s body part gets caught between moving parts or between a stationary object and a moving part. The use of fixed guards and interlocked guards creates a physical barrier, preventing any contact between the worker and hazardous areas. This reduces the risk of crush injuries and provides peace of mind to both employers and employees.

Another common hazard that machine guarding addresses is ejected debris or materials. Machines with high-speed rotating parts can generate projectiles that can cause injuries if they come into contact with workers. By implementing machine guards, these projectiles are contained within the machine, preventing them from reaching workers and causing harm.

Implementing Effective Machine Guarding Practices

To ensure the effectiveness of machine guarding, employers and workers must prioritise proper implementation and maintenance. Here are some essential tips to consider:

- Regular Inspections: Conduct routine inspections of all machine guards to ensure they are in good condition and properly installed. Any damaged or malfunctioning guards should be repaired or replaced immediately.

- Employee Training: Provide comprehensive training to employees on the importance of machine guarding and how to operate machines safely. Educate them on the potential hazards and the correct usage of guards.

- Reporting Issues: Encourage workers to report any issues or concerns they have with machine guards promptly. Establish a reporting system that allows employees to communicate hazards or malfunctions effectively.

- Stay Updated: Stay informed about the latest safety regulations and guidelines related to machine guarding. Regularly review and update your machine guarding practices to ensure compliance with industry standards.

Conclusion

In conclusion, machine guarding is essential for preventing accidents and injuries in the workplace. By implementing proper machine guarding measures, employers create a safe working environment that protects workers from hazards associated with machinery. The use of machine guards effectively addresses specific hazards such as entanglement, crush injuries, and ejected debris, significantly reducing the risk of accidents. Ultimately, prioritising safety through effective machine guarding practices not only protects employees but also enhances productivity and job satisfaction. So, let’s make machine guarding a top priority in our workplaces and ensure the well-being of everyone involved.